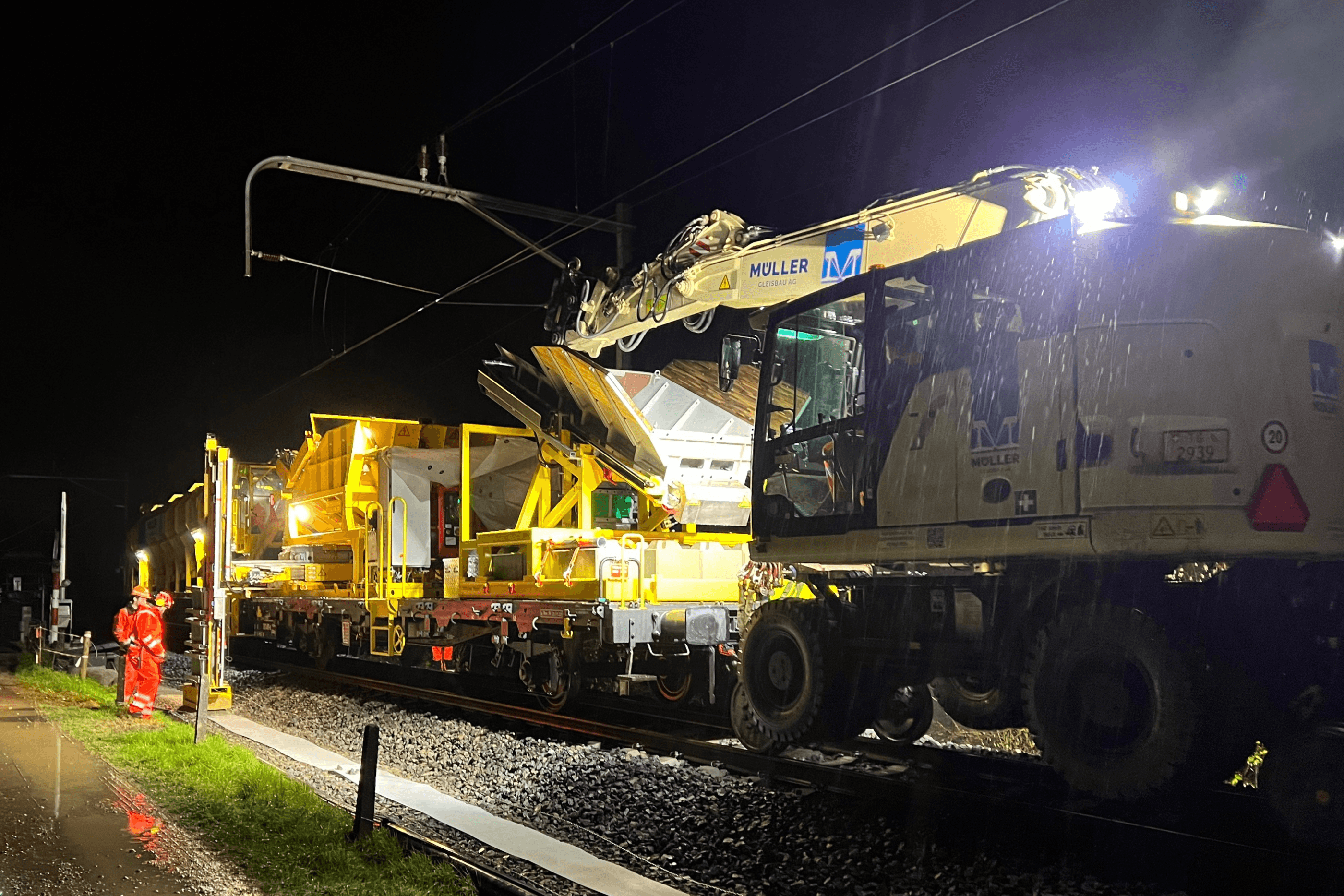

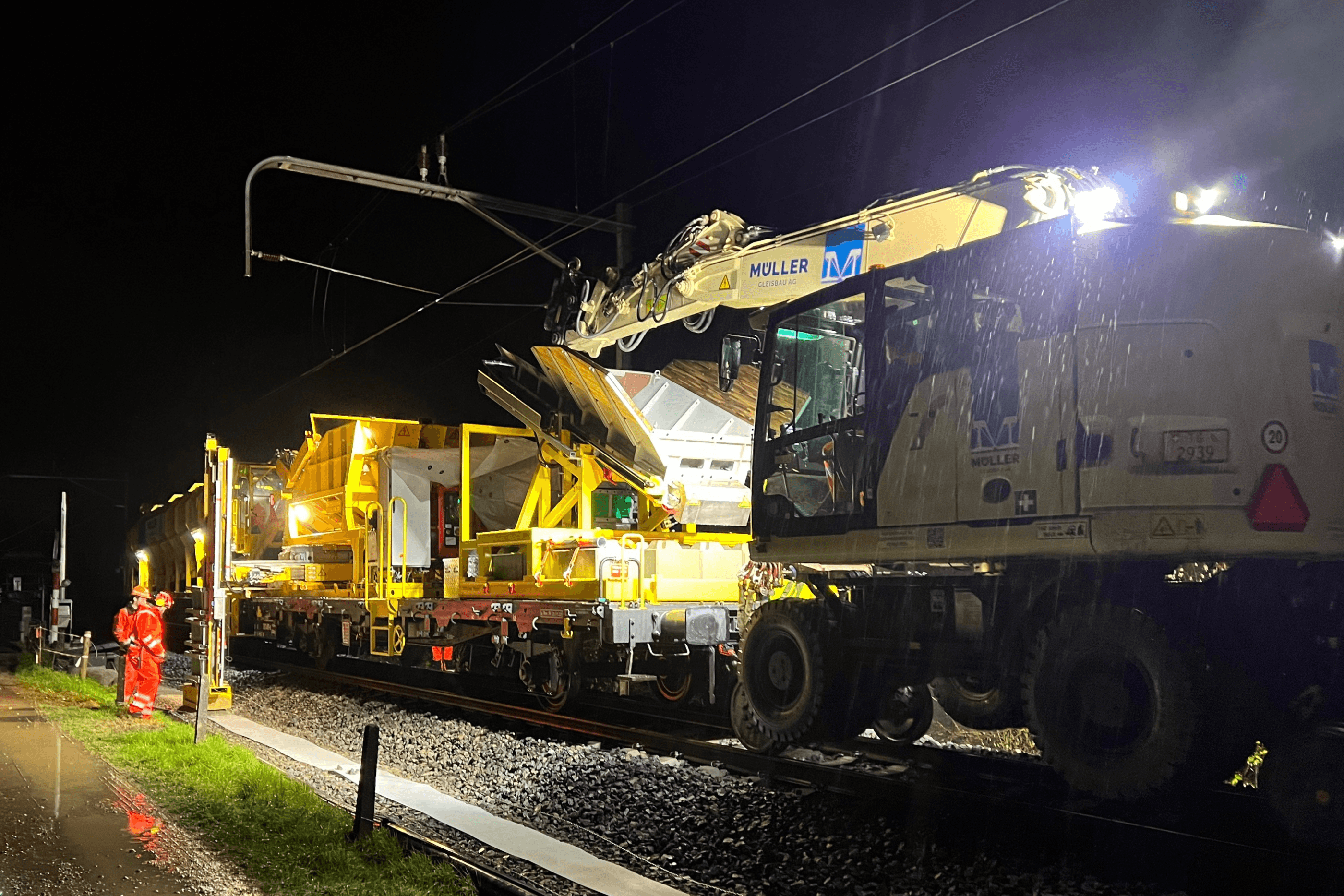

Increased productivity and efficiency thanks to the new gravel-grading machine 2.0. This innovation “made in Switzerland” convinces through numerous benefits for the track layer.

This exciting project required our extensive know-how of hydraulic systems and their automation. The customer was looking for a clever solution for his gravel-grading machine in order to create a ballast track bed with a constant clearance and height difference to the rail. This was also achieved in curves through automatic levelling.

To increase the efficiency of the material usage, the feed was controlled using inclination and position sensors to ensure that only the actual amount of material required was fed to the correct location. To enable the machine to be used in the most energy-efficient way possible, a generator delivers the necessary power via several frequency converters. The hydraulic system was specifically developed for the gravel-grading machine 2.0 and is demand-driven. That means that the power required is calculated and the relevant hydraulic components are controlled individually.

The control is radio-controlled by means of an intuitive user interface with the most important information and alarms.

The customer’s requirements catalogue was very challenging. The old gravel-grading machine, which mainly supported the manual processes when in operation, needed to be replaced. The customer required a gravel-grading machine that is able to produce the ballast layer automatically. Further requirements were energy and material-saving use and quick assembly and disassembly at the place of deployment.

Working closely with the customer, our engineers analysed the different requirements in order to come up with the most compact and stable solution possible.

Here, we focused on three main priorities:

Sensors

The control of the gravel-grading machine is based on the use of displacement and inclination sensors for position control. This enables height limitations, for example with regard to overhead lines, and collision protection measures to be implemented in order to protect the machine.

The material feed and discharge are controlled by means of ultrasonic sensors. This allows the material feed to be adjusted to meet the specific requirements. In addition, overload protection for the arm mechanism was implemented. By means of a pressure sensor and taking into account the lever length, it is possible to determine the force acting on the construction. In the event of overloading, the system is automatically slackened in order to avoid potential mechanical damage.

Control and hydraulic modules

The hydraulic actuation and of the seven frequency converters is by means of a CAN bus-controlled PVG valve bank. This guarantees efficient and precise control of the hydraulics.

An important feature of the system is the demand-drive pumps. The spool positions of the valves are used to determine the actual power requirements. Thus, only the power actually required is produced and unnecessary energy consumption is reduced.

Operation

The machine is controlled via a very precise radio remote control. A display provides the operator with all data relevant to the work. Faults in the system are displayed in plain text to allow rapid troubleshooting in the event of fault.

The new version of the gravel-grading machine is revolutionary. In the field, it is now possible to work faster and with less material waste. Furthermore, the machine reacts flexibly to the environment and, thanks to the programmed movement restrictions, provides for a high level of safety during operation.

The intuitive display supports the workers in the field by providing clear information. Compared to the machine 1.0, this enables the customer to perform the work more efficiently (time, energy and material).

BIBUS HYDRAULIK was able to provide this complex system solution from a single source. We supported the project from the concept to the engineering to the bespoke production and the installation of the unit on the vehicle. This consistency also provides the customer with significant benefits with regard to support and maintenance, as only one contact person is required. Our experience proved to be genuine added value for our customer during this project.

Only one contact person required

With less material waste

Through height limitation and collision and overload protection

Intuitive operation

Engineering and delivery of the complete hydraulic drive system for the largest snow blower in the world. This required our entire developmental expertise – from the concept to the engineering to the programming of the control software.

We are pleased to once again be recognized as an Elite Partner of Danfoss Power Solutions in 2025! This highest distinction in the Danfoss Premier Partner Program reaffirms our continuous commitment to quality, innovation, and outstanding performance.